Power Cables

- Home

- Power Cables

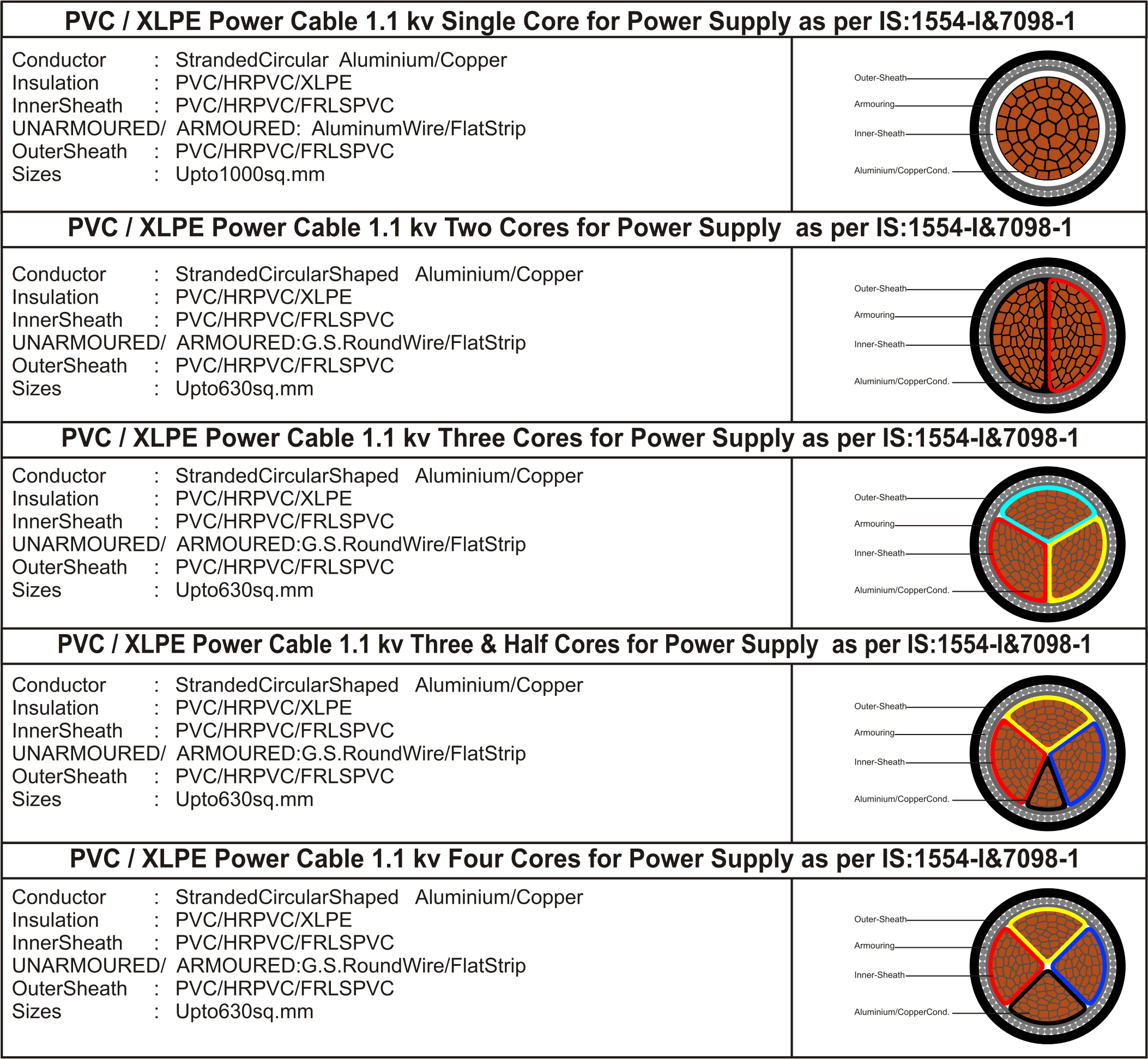

PVC/XLPE INSULATED POWER CABLES

MAHINDAYAL PVC/XLPE Insulated and PVC sheathed Armoured / Unarmoured cable are manufactured with Aluminium / Copper Conductor as per IS: 1554 (Part-I) for PVC insulation and IS: 7098 (Part-I) for XLPE insulation.

Construction of cable

- • Conductor

- • Insulation

- • Laying

- • Inner Sheath

- • Armouring

- • Outer Sheath

- • Final Testing

Conductor

Mahindayal cables are available with both Aluminium & copper conductors. It is manufactured with solid /stranded circular / shaped with Aluminium/Copper conductors.

Construction of conductor

Circular :- with one wire in the centre conductor contains 6, 12, 18, 24, 30…. wire layers in either unilay or opposite helical directions conductor is sized up to 92% compaction.

Shaped :- In all multi core cables from 16 sq mm size conductor are shaped compaction degree in multicore power cable is up to 92% .

Cables with copper conductor are of same construction that of cables with Aluminium conductor except for high tensile strength, superior conductivity, better flexibility and ease of jointing.

All conductors for Mahindayal Cable are strictly as per national and international specifications.

National Specifications : IS 8130

International Specifications : IEC60228 / BS: 6360

Insulation

Mahindayal Cables are designed and manufactured with polymer dielectrics to bear thermal and thermo-mechanical stresses safely at continuous normal and short circuit temperature conditions.

Type of insulations

(A) PVC: THERMOPLASTIC AND DIELECTRIC.

PVC insulation used for Mahindayal Cables take care of over load and short circuit current with coarse and fine protection system.

Advantages of PVC Cables

- 1. A non-hygroscopic insulation almost unaffected by moisture.

- 2. Non-migration of compound permitting vertical installation.

- 3. Complete protection against most forms of electrolytic and chemical corrosion.

- 4. A tough and resilient sheath with excellent fire resisting qualities.

- 5. Good ageing characteristics.

- 6 Not affected by vibration.

(B) XLPE :- THERMO SETTING DIELECTRIC.

XLPE insulation used for Mahindayal cable are with anti oxidant stabilizer and traces of aromatic poly nuclear hydrocarbon thus improving electrical treeing characteristics and mechanical strength of insulation.

Advantages of XLPE Cables.

- 1. Higher Current Rating.

- 2. Higher Short Circuit Rating.

- 3. Longer Service Life.

- 4. For a short time it can withstand maximum 130°C and is favourable to endure short circuit stresses.

- 5. It is less sensitive to the setting of the network protection.

- 6. Because of the thermosetting process taking place due the effect of cross linking, the crack resistance is increased.

- 7. Due to the chemical cross-linking internal stresses are reduced. Consequently the material is less sensitive during manufacturing process to the setting of the cooling gradient.

- 8. The thermal resistivity of cross-linked material is favourably low, compared to thermoplastic material.

- 9. The low dielectric loss is a significant advantage.

- 10. The excellent mechanical features of the insulation improves the protection against external effects.

- 11. The resistance of the XLPE to acids, alkalies is outstanding and is often compensating the adverse environmental influences.

The relative thermal expansion during short circuit dielectric and conductor is therefore limited to minimum both in PVC and XLPE thus limiting displacement of cores in cables during short circuit.

Insulation for Mahindayal cables are strictly manufactured and applied over conductor in accordance with national and international specifications.

National specifications :IS: 5831/IS: 7098

International specifications : BS : 6746/BS : 54671/IEC: 60502

LAYING

Cores are tested on line during production both for physical and electrical characteristics. Control is observed within tight tolerance limits for dimensions in case of PVC/XLPE insulation. For multicore cables cores are laid up on our latest laying up machine equipped with sector correction equipment. In case of XLPE insulated cores the same are cured so as to impart the requisite characteristics both electrical and mechanical and then are laid up.

INNER SHEATH

Laid up cables are provided with inner sheath with high quality of PVC which acts as bedding for steel wire / strip armouring. Wherever required, filler cords are provided to maintain the circularity to laid up cables.

In Mahindayal Cable-polymers used for inner sheath are softer than insulation or outer sheath & are compatible with temperature ratings of cables & do not have deleteriocus effect on any other component of cable.

Inner sheath is applied either with extrusion or by wrapping. In Mahindayal Cables though the inner sheath is closely applied on the laid up cores, same can be stripped with ease without damaging insulation.The inner sheath dimensions are maintained strictly in accordance with laid down specification. Specification For PVC Cables IS: 1554 (Part-I) For XLPE Cables IS:7098 (Part-I)

ARMOURING

Mechanical protection to the cable is provided with armouring. Mahindayal single core cables are armoured with Aluminium or Aluminium alloy wire/strips, thus avoiding magnetic hysteresis losses on A. C. System. Multicore cables are provided with galvanised steel wire/strips.Mahindayal cables are provided with galvanised wire armouring, where cables are to run vertically and are subjected to stresses. Mahindayal cables armour wires/strips are of low resistivity material and meet the requirements of IS :3975. Mahindayal armoured cables are with almost 95% armour coverage.

OUTER SHEATH

All Mahindayal Cables are provided with PVC/polymer outer sheath.Mahindayal Cables are manufactured with various characteristics of sheathing compounds.

General purpose sheathing Compound ST1

Heat resistant Compound for sheath (H.R.) ST2

Fire Retardant Low IEC754PartI

Smoke Compound IEC 60332 Part I& III

(FRLS) IEEE-383

ASTM-2843

ASTM-2863

Flame Retartant Compound (FR) to EIL Specn.

Ultra Voilet Radiations Resistance Compound to ASTM G-53.

Anti Rodent and Anti Termite Compound.

PVC compounds used for Mahindayal Cables are of various grades to meet specifications IS: 5831.

In order to be identified, Mahindayal Cables have their name embossed/printed on outer sheath at regular intervals on the outer sheath of Mahindayal Cables, Voltage Grade, cable size, trade name & year of manufacture are embossed, as desired. Cables are sequentially marked for length at every metre throughout its length.

Final Testing

All the test are carried at our quality assurance and testing laboratory as per requirement of the relevant quality standards or as per clients stipulation.